Duke Energy is turning hog waste into electricity, with the electric utility announcing its second swine-waste-to-energy program in North Carolina, WHQR reports. The energy giant is just one of many companies and other entities that are looking for ways to generate clean energy from waste products.

North Carolina, with a huge pork industry, is home to some 9 million hogs. The massive amounts of waste that the swine produce creates disposal and environmental challenges. Now, Duke has paired with two other companies to capture methane gas from waste at several hog farms. Those companies — Carbon Cycle Energy and Optima KV — will clean the methane before shipping it to Duke’s power plants, where it’ll be burned to make electricity.

The company expects to use the hog-waste methane to generate about 0.2% of its total electrical output by 2021. It’s a small amount, but officials say it’s a start, and they expect to bring more hog farms into the program.

North Carolina has a unique law that requires electric utilities as a source of fuel, Fortune notes.

Duke is far from alone in converting waste into clean energy.

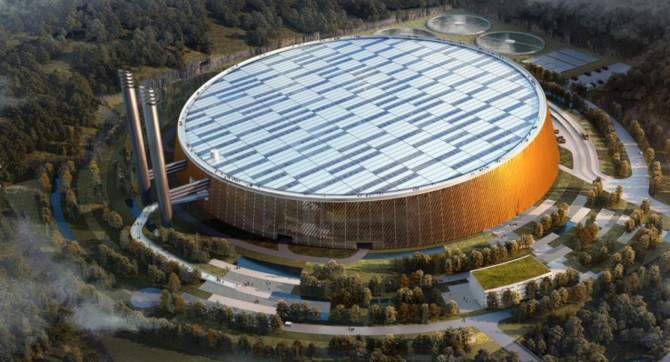

The Chinese megacity of Shenzhen is building what will become the world’s largest waste-to-energy plant, Fast Company reported earlier this year. When it opens in 2020, the plant will be capable of burning 5,000 ton of trash each day, and will turn that burning trash into electricity.

It’s one of 300 waste-to-energy plants China plans to build over the next three years. Burning the trash will release carbon dioxide and other pollutants, supporters concede, but they point out the tremendous benefit of reducing the massive landfills that serve China’s huge and fast-growing cities.

The Shenzen plant’s actual operations will be green, though, powered by rooftop solar panels, according to Fast Company.

Other waste-to-energy developments around the world:

Connecticut Green Bank Supports Food Waste-to-Energy Plant

A Connecticut company is building a $12 million food-waste-to-energy plant, the Hartford Business Journal reports. The plant in the town of Southington will produce 1.1 megawatts of electricity. Funding includes a $2 million loan from the Connecticut Green Bank, according to the Business Journal.

The facility will be powered by organic waste from restaurants and other food waste producers. Besides electricity, the plant will produce about 10,000 tons of compost per year.

Bryan Garcia, president and CEO of the Connecticut Green Bank, says the project will set an example for other communities interested in sustainable energy. It will also help reduce food waste that would otherwise end up incinerated or in a landfill, the Business Journal reports.

From Toilet to Energy in South Korea

Researchers in South Korea have found a new method to turn human waste into renewable energy, Phys.org reports. Scientists with the Ulsan National Institute of Science and Technology have developed a waterless toilet system that uses a “natural biological process” that breaks down human waste into a dehydrated, odorless material similar to compost, according to Phys.org.

That compost is put in a digestion tanks, where microbes convert it into methane and carbon dioxide. The methane can be burned as a heating fuel, while the carbon dioxide can culture green algae for biofuel production.

A prototype of the toilet system is currently on display at the university’s campus. If the prototype is a success, researchers plan to expand it.

Australian Start-Up Signs Two Global Deals

Canadian paper and pulp producer CanFor says it will use technology developed by Australian renewable energy start-up Licella to turn biomass waste into biocrude, a petroleum substitute, the companies announced.

Licella also signed a A$10 million ($7.4 million) contract with the UK’s Renewable Chemical Technologies Limited to convert hard-to-recycle plastics into biofuel. Licella will build the world’s first commercial hydrothermal waste upgrading plant in Australia; after testing it, the technology will be exported to the UK, according to an announcement from the University of Sydney’s School of Chemistry.

New Waste-to-Energy at Delhi Landfill

In India, the capital city of Delhi has opened a waste-to-energy plant at one of its three landfills. The plant can process 1,300 metric tons of garbage per day — about half of the garbage received at the landfill daily — and convert it into 24 megawatts of electricity, the Times of India reports.

Waste-to-energy plants already exist at Delhi’s other two landfills, producing a respective 12MW and 16MW of electricity daily, according to the Times.

A British company says it has co-invented technology that can turn landfill gas into liquid diesel and gasoline fuel that is suitable for all motor vehicles, Renewable Energy Focus reports.

Renovare Fuels Ltd. has a pilot program in place and is raising funds to build a mobile, commercial-scale unit that will let it run demonstrations for the U.K.’s six main landfill operators. The company plans to then build a full-scale production facility.

Such a facility could produce up to 190 barrels of fuel per day, Renovare estimates. The company says it’s already seeing interest in its new technology from potential clients i the Middle East and Southeast Asia, according to Renewable Energy Focus.

The proposed Shenzhen East Waste-to-Energy Plant is expected to incinerate and process 5,000 tonnes of waste per day.