By: Dennis P. Calvert, President and CEO of BioLargo, Inc.

Freshwater has historically been the base fluid essential for fracking, sweeping, and oil sands recovery because it has been abundant and readily available, and because of its low cost. Unfortunately, all of that is now changing due to a longer than expected global drought, and the industry is examining new options and technologies to find new sources of water.

At BioLargo, we believe that “everybody deserves affordable clean water.” In pursuit of that belief, we have developed and are introducing the breakthrough AOS Filter, which is currently in commercial pilot testing at the University of Alberta. We expect this invention to impact the entire water industry because it has delivered unprecedented results in both decontamination and disinfection.

The Canadian government’s Natural Sciences & Engineering Research Council (NSERC) Industrial Research Chair invited BioLargo to help clean very large amounts of toxic produced water from oil sands recovery operations in Canada. BioLargo cofounded the chair with Suncor, Syncrude, Shell, Canadian Natural Resources, Total, Epcor, Alberta Innovates, Alberta Environment and the University of Alberta.

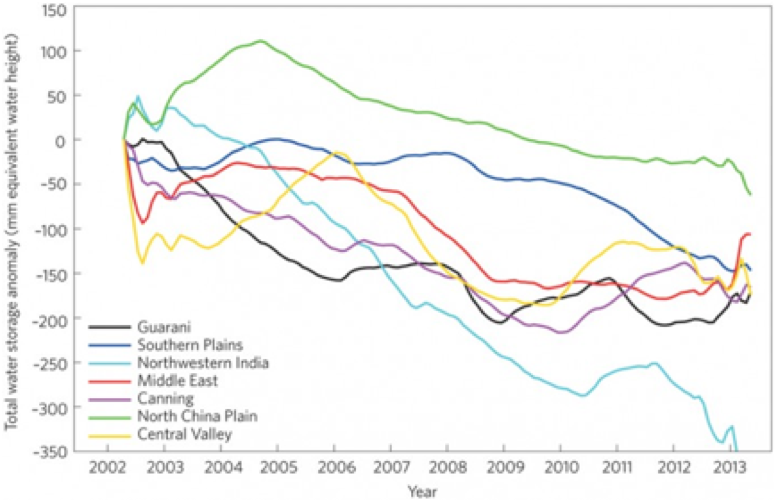

Based on data from decades of observations, NASA scientists have been predicting the current global drought and warning that it may intensify throughout the balance of this century — and could in fact become the worst drought of the past 1,000 years. Since 2002, NASA’s GRACE satellites have measured massive groundwater losses around the globe. Using over 20,000 monitoring wells, the USGS has confirmed groundwater losses all across the nation and in central California of five feet in just one month and 200 feet in the past few years. This 11-year chart from NASA demonstrates declining groundwater globally, including California’s Central Valley.

Image by J.T. Reager, NASA Jet Propulsion Laboratory.

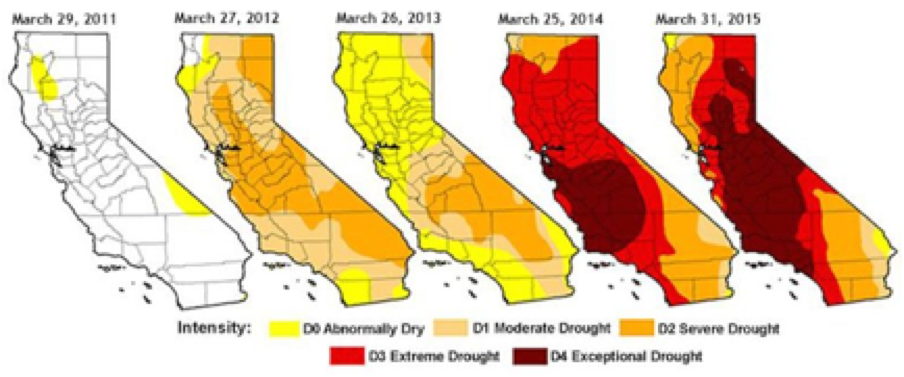

The following chart is from the U.S. Drought Monitor and demonstrates the severity of the current drought that is certain to impact heavy fracking operations in California.

If NASA’s predictions come true, new sources to replace freshwater for fracking and oil sands recovery will certainly be required, and new technologies to enable using those new water sources cost-effectively will become essential.

Vikram Rao spent more than 30 years with Halliburton as senior vice president and chief technology officer and is now a senior technical advisor to BioLargo. He points out, “Massive amounts of water used in new wells and in sweeping or flooding secondary recovery operations do not need to be freshwater. Reused water and underground brackish water are two obvious sources for replacement. In fact, brackish water is even preferred over freshwater if its salinity is close to 5,000 parts per million (PPM).”

According to Rao, “For drilling operations, a little salinity will prevent swelling of clay, and since clay is a component of shale, preventing swelling is useful in the drilling and fracturing phases of operations. For water flooding, a little salinity is useful in unlocking oil from the formation. A technical explanation is that the salinity has to be monovalent, such as from Na (sodium). In one mechanism, oil is bound to the rock by a divalent species. The monovalent exchanges ions, thus releasing the oil from the rock.”

A single well can require as much as 6 million gallons of water, and about a third of that returns to the surface as flowback water that potentially can be treated and reused, Rao says. “Before the flowback can be reused, it must be treated to reduce the high salinity, which can range between 15,000 and 250,000 PPM, and it must treated with cost effective disinfection to manage the high levels of bacteria,” he explains.

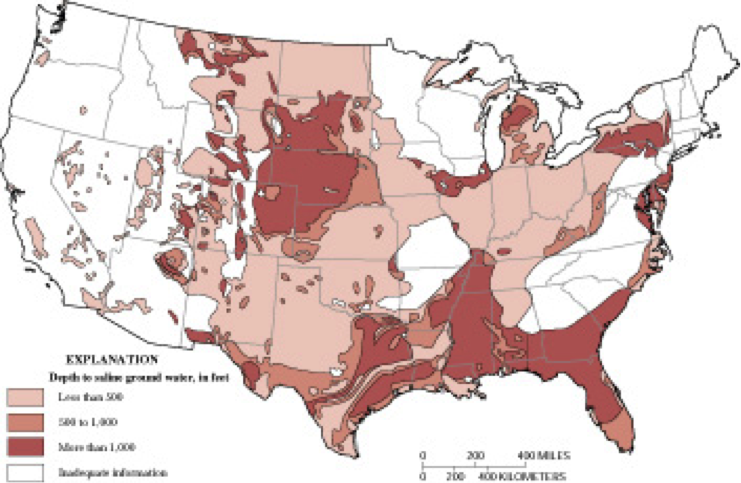

Brackish groundwater is abundant almost everywhere and at reasonable depths for harvesting. With typical saline levels of close to 5,000 PPM, it appears to be the best choice for replacing freshwater. This USGS map indicates how vast brackish groundwater is in the United States. Note that the white areas do not indicate an absence of brackish groundwater; rather, they indicate that those areas have not yet been measured and mapped.

As plentiful and available as brackish groundwater is, it has obvious obstacles, most notably the presence of sulphates and subsurface bacteria. According to Tommy Taylor of Fasken Oil & Ranch, the largest private driller in Texas, “The problem with this particular water is that it has sulfate in it. If the sulfate combines with barium and strontium — elements that are found in underground water lying alongside underground oil and gas formations — the sulfate can ruin your well.”

Rao and Ken Code, BioLargo’s chief science officer, both agree that subsurface bacteria from backflow and brackish groundwater can pose dangers, with ancient species of bacteria that have evolved and become anaerobic from living at depths without oxygen for so long — bacteria that could turn out to be a nightmare once released to the surface where oxygen is plentiful.

Taylor confirms that the owner of Faskin Oil & Ranch wants to preserve their freshwater aquifer and says his operation is now using membrane technology to desalinate brackish groundwater from the deeper Santa Rosa Aquifer and chlorine dioxide to disinfect any potential bacteria. They also have to treat the water to remove sulphates.

Chlorine dioxide is a gas that is highly toxic and can be lethal. In addition to the obvious dangers, the cost to install the infrastructure to inject the gas into water must be taken into consideration; so must the costs of maintenance, operation and the chlorine itself.

Chlorine dioxide may be today’s first choice to disinfect brackish groundwater, but the industry wants a solution that is better — and that comes at a lower cost. Other disinfection technologies, such as UV treatment, chemicals or advanced oxidation systems, are available, but they are expensive. In the end, the most cost-effective and safest technology will become the new gold standard.

Reverse osmosis is today’s most cost-effective technology to desalinate the brackish ground water and the flowback, but the biggest obstacles are the its high energy requirements, and the cost of degradation of membranes associated with biofilm management. Hiroko Kasama, lead consultant for Global Water Intelligence, believes biofouling is one of the most significant challenges in RO desalination because biofilm from bacteria growth on the filter surfaces causes clogging that greatly increases energy requirements. It also shortens the filters’ lives, requiring more frequent replacement of the costly membrane filters.

Brackish groundwater and flowback water are already being used by a handful of drillers and operators as replacements for freshwater and are living proof that it can be done. The rising pressure on conserving and managing fresh water sources will push demand for cost-effective solutions that enable these replacement strategies to be deployed. New technologies should be expected to work better than chlorine dioxide and current desalination biofilm disrupters, and they absolutely must cost less.

Brackish groundwater and backflow water may not only be the best viable options, but are arguably the only options to replace vanishing freshwater.

BioLargo has developed the next generation water treatment technology to address the need for lower cost desalination; cost effective, high-speed, high-level water disinfection; and removal of sulphates and a host of contaminants like aromatics such as BTEX and napthenic acids commonly associated with oil sands, fracking and petroleum derivatives.

BioLargo’s AOS Filter is being showcased at a symposium this August at the University of Alberta.

This article was brought to you by BioLargo. BioLargo, Inc. designs and delivers nature’s disinfectant iodine. Its technologies include AOS Filter, CupriDyne, and Isan system.